Henso have the largest product scope in the industry (110 products in over 580 sizes), which caters to almost the entire spectrum of a patient’s need. Each product has been designed and manufactured to deliver maximum performance and safety. We have award from The Chamber of Commerce in China for outstanding export performance.

Since the moment of establish, Henso are committed to offer one-stop supply for medical products, to reduce medical expense by supply quality products with affordable cost. We are efforts for better life of human beings.

While most company only produce or supply one or few items, but most agent want to enrich it’s product scopes to improve supply chain and maintain marketing vatility. Henso start efforts to offer one-stop solution for medical supplies.

Today, after several years rapid development, Henso has entrenched itself as a global player specialized in manufacture and distributor of medical products, with a presence in 36 countries. A group with five (5) subsidiary factories and eight (8) joint venture manufacture base. A product scope more than 110 products, with a 230 plus distributors network in China and abroad.

PURSUIT ZERO DEFECT QUALITY

Manufacture zero-defect products is our goal of quality. We have built a series online and manual quality control measures into each stage of raw material procurement, manufacturing and packing cycle.

Our Quality Control standards conform to ISO 13485:2016 and European Medical Device Directive 93/42/EEC Annex V. As a result, our products have been authorized to label prestigious CE mark. We also registered with US FDA, some items have obtain 510K.

GOOD MANUFACTURING PRACTICES

Our Manufacturing plant conforms to GMP, a WHO proprietary benchmark. This standard is evident in the physical ambience of our plant, the air and water quality, manufacturing technology, packaging and the sterilization process. Ambience: Special micro and HEPA filter at all air handling units ensure minimal contamination in all manufacturing areas. Micro organism and particle concentration levels are carefully monitored by the micro-biological lab to keep these levels within safe limits. Employees undergo periodic medical checkup to maintain high standards of health and hygiene. All clean rooms are provided with a three step change room and air showers at the entrance to ensure a dust-free environment.

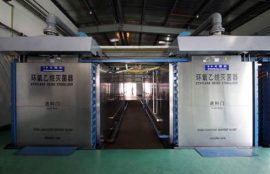

PACKING AND STERILIZATION

Our products are packed by most modern packaging machines, to ensure minimal risk of contamination or damage during transportation. We use Ethylene Oxide or Gamma Radiation to sterilize the product, as per ISO 11135/EN 550 standards, each batch were release after strict inspection.